Product Description

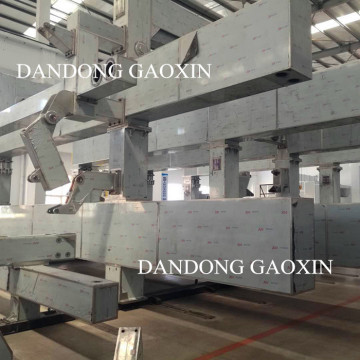

Double Layer Cardboard Paper Machine

Double Layer Paper Machine

Cardboard Paper Machine

Paper Making Machine

Sample information for Double Layer Cardboard Paper Machine

Products: Cardboard paper

Quantitative Range: 80-120g/m

Trim Width: 4000mm (after rewinder machine)

Daily Capacity: 150t/d

(100g/m2,300m/min,22h,100% production efficiency)

Design Speed: 350m/min

Working Speed: 300m/min

Crawling Speed: 25m/min

Dynamic Balance Speed: 400m/min

Wire Width: 4500mm

Lip Width of Headbox: 4350mm

Gauge: 5100mm

Transmission Form: Full digital AC frequency conversion motor frequency conversion speed division drive

Arrangement Form: Double floor Layout

Arrangement: Left/ right hand machine(looking the headbox from reeling machine, if the transmission motor is on the left, it`s left-hand machine; if the driving motor is on the right, it`s right-hand machine.

Dryness of Each Section:

out of wire section:≥20~22%

before getting into dryer:≥44~46%

dryness of finished paper:92%

Lateral shrinkage: ≤3.5~4.5%

Horizontal moisture difference: ≤±1%

Horizontal quantitative difference: ≤±1.5%

Compressed air pressure : ≤0.6MPa

Paper Making Machine Process Flow

Air cushion typed headbox( 2 sets)→double layer wire section→ one vacuum suction φ600→two jumbo press(φ1350/φ1350)→16 pieces of φ1800 dryer(8+8)→ sizing machineφ905/φ900) → 8 pieces of φ1800 dryer→ double roll calender machine (φ600/φ650→B/M placeholder → horizontal reeling machine→frame reeling machine.

.png) Contact Now

Contact Now